This is Part 4 of our 6-part Deep Dive series on neuromorphic computing—the brain-inspired processors achieving 1,000× efficiency improvements over GPUs at the edge.

← Part 3: IBM NorthPole | Series Index | Part 5: The Automotive Bet →

[🧠] Sapien Fusion Deep Dive Series | February 4, 2026 | Reading time: 5 minutes

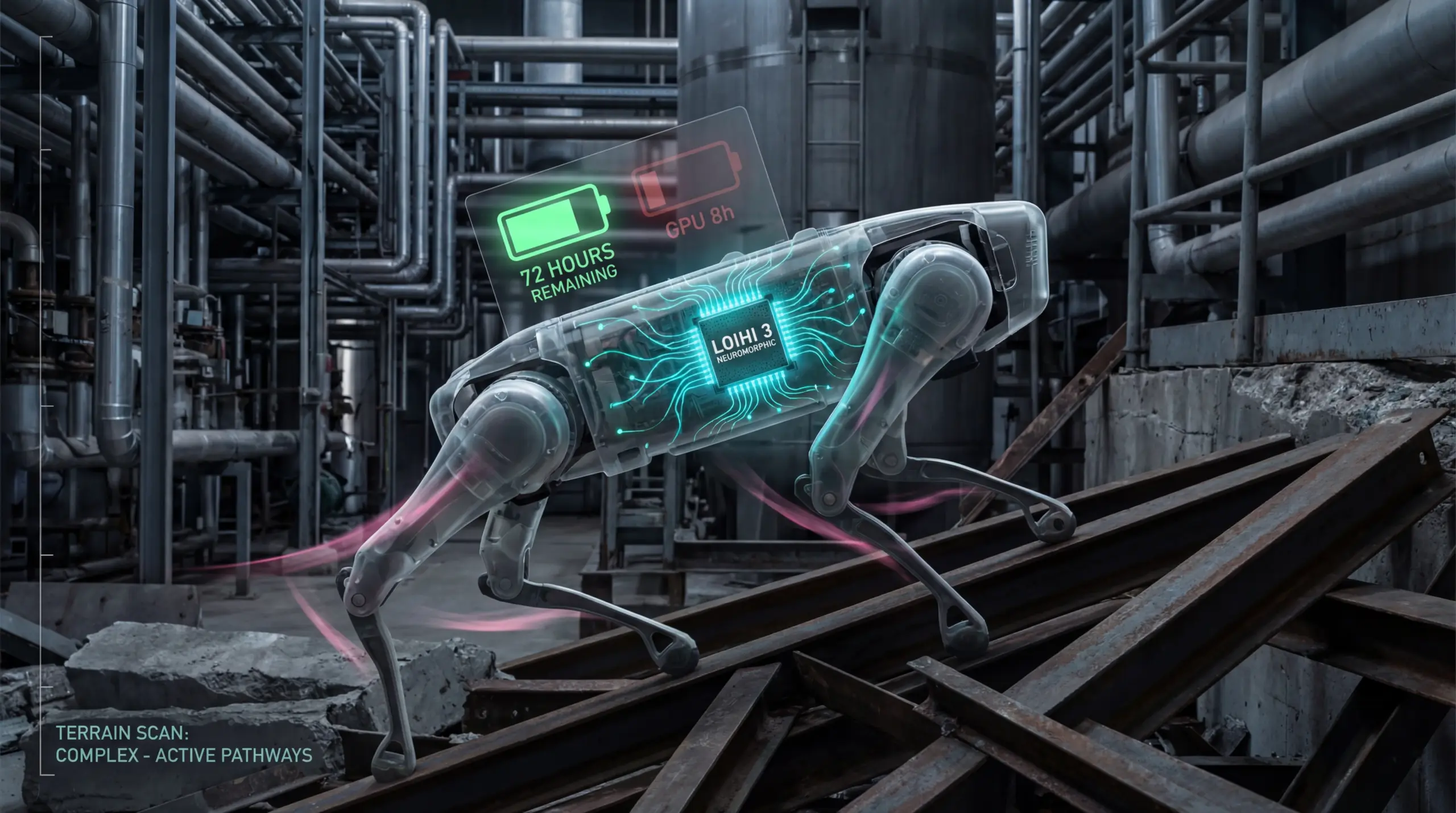

72 Hours on One Charge

The ANYmal D Neuro quadrupedal robot represents the moment neuromorphic computing transitioned from laboratory curiosity to commercial reality. This isn’t a research prototype demonstrating incremental improvements. This is a production-ready platform achieving capabilities that GPU architectures fundamentally cannot match.

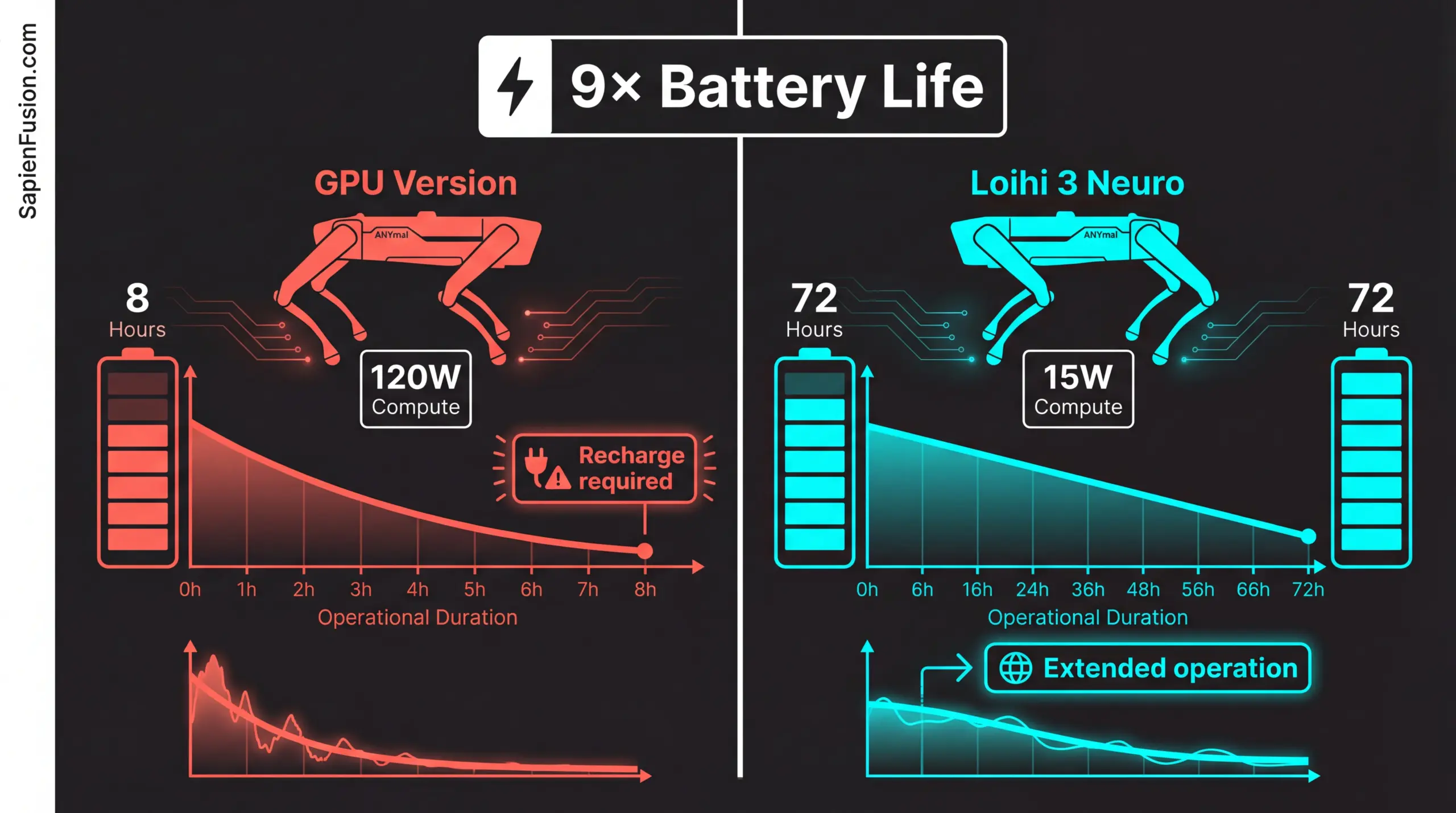

Seventy-two hours of continuous autonomous operation on a single battery charge. Nine times longer than the GPU-powered predecessor managed. The same robot, the same missions, the same operating environment—only the processor changed.

The Platform

ANYbotics’ ANYmal platform established itself as a leading quadrupedal robot for industrial inspection before neuromorphic integration. The system navigates complex environments autonomously, climbs stairs and obstacles, operates in hazardous conditions, and performs visual inspection tasks requiring sophisticated AI processing.

The standard ANYmal equipped with NVIDIA Jetson hardware achieved an eight-hour operational duration between charges. For many industrial inspection scenarios—pipeline monitoring, facility security patrols, hazardous environment surveys—eight hours proved insufficient. Operators needed robots that could complete full inspection cycles without interruption, operate through entire shifts without charging breaks, and deploy to remote locations where charging infrastructure doesn’t exist.

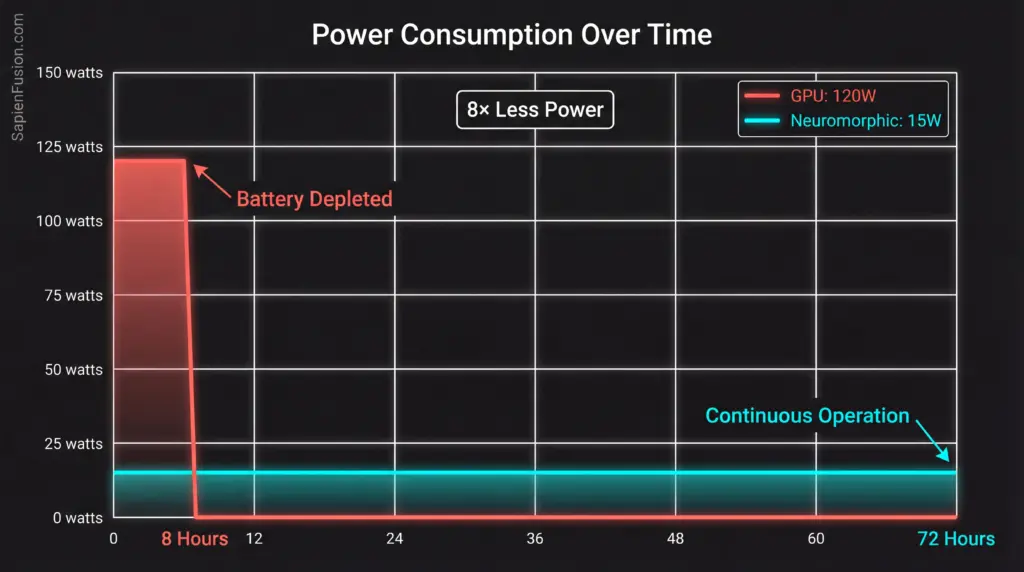

The bottleneck wasn’t mechanical. Battery technology, locomotion efficiency, and mechanical reliability all supported longer missions. The constraint was computational—running perception, navigation, and decision-making algorithms on GPU hardware consumed power faster than batteries could sustain for extended durations.

The Loihi 3 Integration

Intel partnered with ANYbotics and ETH Zurich to integrate Loihi 3 neuromorphic processors into ANYmal D, creating the “Neuro” variant. The integration replaced GPU-based perception and navigation systems with neuromorphic equivalents while maintaining mechanical design, battery capacity, and operational capabilities.

The technical challenges went beyond simple hardware swapping. Conventional deep learning models trained for GPU execution required conversion to spiking neural networks compatible with Loihi 3’s event-driven architecture. Navigation algorithms designed around frame-based processing needed to be redesigned for asynchronous spike-based computation. Control systems expecting predictable GPU latency had to adapt to variable neuromorphic response times.

The development team addressed these challenges through iterative refinement over eighteen months. Early prototypes demonstrated efficiency advantages but struggled with accuracy degradation during conversion from conventional to spiking neural networks. Mid-stage development achieved accuracy parity but revealed integration issues with existing control systems. Final optimization balanced efficiency, accuracy, and system integration to achieve production readiness.

The 72-Hour Breakthrough

January 2026 public demonstration validated the integration. ANYmal D Neuro operated continuously for 72 hours, performing autonomous inspection missions in industrial facility mockup environments. The robot navigated stairs, traversed obstacles, performed visual inspections, detected anomalies in real-time, and adapted to changing conditions—all while consuming power at rates enabling three-day operation on a single charge.

The performance metrics reveal the magnitude of improvement. The GPU-powered ANYmal D consumed approximately 120 watts for compute during active operation, requiring 960 watt-hours for eight-hour missions. The Loihi 3-powered ANYmal D Neuro consumed approximately 15 watts for equivalent compute, requiring just 1,080 watt-hours for 72-hour missions—the same battery capacity delivering nine times longer operation.

This efficiency advantage doesn’t come from reduced computational capability. The neuromorphic variant performs identical perception tasks, processing visual data from multiple cameras, executes comparable navigation algorithms planning optimal paths through complex spaces, makes equivalent real-time decisions responding to environmental changes, and maintains similar reliability metrics across extended operation.

The improvement stems purely from architectural efficiency—event-driven processing consuming power proportional to information content rather than frame rate, temporal sparsity activating neurons only when relevant events occur, and memory co-location eliminating power-hungry data transfers.

Operational Impact

The implications for industrial robotics deployment are substantial. Current inspection protocols require human operators to manually inspect facilities, equipment, and infrastructure at regular intervals. These inspections occur in hazardous environments, including chemical plants where toxic exposure poses risks, offshore platforms where weather creates danger, confined spaces where accident response proves difficult, and high-altitude structures where falls threaten safety.

Deploying robots for these inspections reduces human risk but introduces new constraints. Eight-hour operational limits force multiple charging cycles per shift, require operators to position charging stations throughout facilities, limit deployment range from charging infrastructure, and interrupt inspection sequences mid-mission.

Seventy-two-hour operation transforms deployment economics. A single robot can complete entire weekly inspection cycles without charging, patrol large facilities without positioning charging stations throughout the site, deploy to remote locations inaccessible to charging infrastructure, and operate continuously through weekend periods when human staff are minimally present.

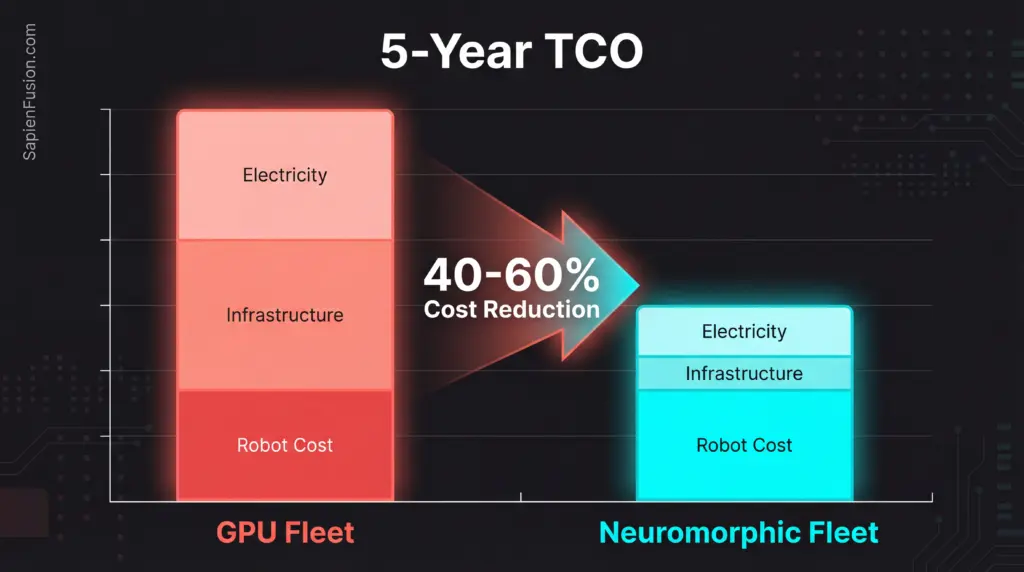

The total cost of ownership calculation shifts dramatically. Industrial facilities calculating five-year deployment costs compare robot purchase price against operational savings from reduced human inspection labor, decreased accident risk and associated insurance costs, improved inspection consistency catching issues earlier, and enhanced facility uptime from continuous monitoring.

An eight-hour operation meant robots needed to compete against human inspectors on direct labor cost alone—a challenging comparison given upfront capital expenditure. Seventy-two-hour operation means robots deliver capabilities humans cannot match at any cost—continuous presence, consistent attention, access to hazardous environments, and immediate anomaly detection. The value proposition becomes enabling rather than cost-reducing.

Market Validation

Early commercial deployments validate the operational advantages. A European chemical manufacturer deployed three ANYmal D Neuro units for facility inspection, replacing previous manual inspection protocols. The deployment achieved continuous monitoring coverage across 24-hour periods with automated reporting of detected anomalies, reduced human exposure to hazardous environments by approximately 85%, and identified equipment degradation earlier through continuous monitoring versus periodic manual inspection.

The economic return manifested within eighteen months. Reduced labor costs from eliminated manual inspection shifts, decreased insurance premiums from improved safety profile, avoided downtime from earlier fault detection, and enhanced regulatory compliance from comprehensive documentation, combined to justify the capital investment with ongoing operational savings.

An offshore oil platform operator tested ANYmal D Neuro for inspection protocols in weather conditions restricting human access. The robot maintained inspection schedules during storm periods when human inspectors couldn’t safely deploy, identified critical issues requiring intervention before conditions deteriorated, and provided remote operators with real-time situational awareness during adverse weather.

Mining operations deployed ANYmal D Neuro for underground tunnel inspection in conditions where extended human presence posed ventilation challenges. The 72-hour operation enabled comprehensive mapping and inspection of extensive tunnel networks on single deployment cycles, eliminating the logistics of multiple charging cycles in remote underground locations.

Technical Lessons

The ANYmal D Neuro development revealed important lessons about neuromorphic integration. The accuracy gap during conventional-to-spiking network conversion required careful attention to temporal coding schemes, activation function mapping, and training methodology adaptation. The development team achieved accuracy within 2% of the GPU baseline through iterative refinement, but the process demanded specialized expertise and significant development time.

System integration complexity exceeded initial estimates. Conventional control systems designed around predictable GPU latency struggled with neuromorphic processors’ variable response times. The team redesigned control loops to accommodate asynchronous processing while maintaining stability and responsiveness.

The software development workflow differs substantially from conventional approaches. Debugging spiking neural networks requires visualization tools showing temporal dynamics and spike patterns rather than static activation values. Performance optimization involves tuning temporal parameters and event thresholds rather than batch sizes and learning rates. Testing protocols must validate behavior across time rather than evaluating single forward passes.

These challenges represent temporary barriers rather than fundamental limitations. The development community actively addresses tooling gaps, shares best practices, and standardizes methodologies. Organizations beginning neuromorphic development now benefit from lessons learned through early adopter struggles.

The Broader Implications

ANYmal D Neuro demonstrates neuromorphic computing’s readiness for commercial deployment in demanding applications. This isn’t a research demonstration or a limited pilot—it’s a production robot operating in real industrial environments performing mission-critical tasks.

The nine-times improvement in battery life proves neuromorphic efficiency advantages translate to meaningful operational capabilities. The successful integration shows that conventional robotics systems can incorporate neuromorphic processors without complete redesign. The commercial deployments validate market demand for the capabilities that neuromorphic architectures enable.

For robotics companies, the strategic question becomes whether to integrate neuromorphic processing now or wait for ecosystem maturity. Waiting means simpler development with mature tools, but concedes competitive advantage to early movers. Integrating now requires navigating immature tooling and scarce expertise, but establishes market positioning before neuromorphic integration becomes table stakes.

For industrial operators, ANYmal D Neuro demonstrates what becomes possible with neuromorphic processing. Inspection missions previously impossible due to power constraints become routine. Deployment scenarios requiring infrastructure investment become feasible without modification. Operational capabilities previously demanding human presence become automated and continuous.

The Timeline

ANYbotics and Intel achieved the ANYmal D Neuro integration through an 18-month development cycle beginning mid-2024. This timeline included initial proof-of-concept demonstrating basic functionality, algorithm conversion and optimization, achieving accuracy parity, system integration resolving control and interface challenges, field testing validating performance in real environments, and commercial production preparation for customer deployment.

Organizations beginning similar integrations now benefit from established methodologies, available reference implementations, a growing developer community, and maturing toolchains. The timeline compresses as the ecosystem develops, though specialized expertise remains necessary and conversion complexity persists for sophisticated applications.

The competitive window narrows as neuromorphic integration transitions from differentiator to requirement. Robotics vendors integrating now establish market position and operational expertise before competitors achieve equivalent capability. Those waiting find themselves competing against established players with years of deployment experience and optimized implementations.

What ANYmal Proves

The ANYmal D Neuro demonstrates that neuromorphic computing delivers on efficiency promises in production environments, integrates successfully with existing robotics platforms despite tooling immaturity, enables deployment capabilities impossible with conventional architectures, and justifies investment through measurable operational advantages.

This proof point eliminates the uncertainty surrounding neuromorphic commercial viability. The technology works. The efficiency gains materialize. The operational advantages justify development investment. The market demand exists.

The question facing robotics companies and industrial operators shifts from whether neuromorphic computing delivers value to whether they move quickly enough to capture competitive advantages before the window closes